Top 10 Ready Mix Concrete Companies in Bangladesh

Ready Mix Concrete Companies in Bangladesh provide high-quality, durable, and sustainable concrete solutions for modern residential and commercial construction. The construction industry in Bangladesh is expanding rapidly, driven by large-scale infrastructure, residential, and commercial developments.

From bridges and highways to high-rise buildings and industrial facilities, ready-mix concrete (RMC) plays a vital role in ensuring quality, durability, and sustainability.

Choosing the right ready mix concrete company in Bangladesh is essential, as the quality of concrete directly impacts the strength and lifespan of any structure.

Among the top ready mix concrete suppliers in Bangladesh, Bashundhara ReadyMix & Construction Industries Ltd. (BRMCIL) stands out for its premium ready-mix concrete solutions, strict quality control, and dedication to innovation and sustainability.

Let’s explore the top 10 ready mix concrete companies in Bangladesh, leading the modern construction revolution.

1. Bashundhara ReadyMix & Construction Industries Ltd. (BRMCIL)

Bashundhara ReadyMix & Construction Industries Ltd. (BRMCIL), a concern of Safwan Bashundhara Global, is one of the leading ready-mix concrete providers in Bangladesh.

It operates multiple ready-mix concrete plants equipped with advanced mixing technology to produce high-performance concrete for residential, commercial, and industrial projects.

Key Features:

- High-quality concrete grades like M20, M25, M30, and specialized mixes for pre-stressed and composite concrete needs.

- Fleet of modern mixer trucks and transit mixers ensuring reliable delivery across Dhaka and beyond.

- Focus on sustainable construction practices, minimizing waste and promoting eco-friendly materials.

- Robust quality control systems and on-site testing laboratories.

- Fair and transparent ready-mix concrete price in Bangladesh with guaranteed consistency.

With innovation, sustainability, and construction excellence, BRMCIL continues leading the market and setting benchmarks for premium concrete solutions.

2. NDE Readymix Concrete Ltd.

Established in 2009, NDE Readymix Concrete Ltd. is a trusted ready-mix concrete supplier catering to both public and private infrastructure projects.

The company operates several mixing plants and offers high-strength concrete products tailored to Bangladesh’s construction needs.

Highlights:

- Advanced ready-mix concrete batching plants.

- Dedicated quality assurance and technical support team.

- Continuous investment in research and development to improve concrete strength and durability.

3. Mir Group

A pioneer in Bangladesh’s ready-mix concrete market, Mir ReadyMix began operations in 2003.

It is known for its commitment to quality and innovation in construction materials.

Key Features:

- Multiple ready-mix concrete plants strategically located for efficient supply.

- Offers specialized concrete solutions for high-rise and infrastructure projects.

- Strong reputation for on-time delivery and strict quality control.

4. MI Cement Factory PLC (Crown Ready Mix)

Under the Crown Cement brand, MI Cement Factory PLC offers premium ready-mix concrete using its own leading cement products.

This vertical integration ensures consistent mix design and high-quality concrete.

Highlights:

- Uses composite cement to enhance concrete durability.

- Supports residential and commercial construction projects.

- Focused on sustainable construction and environmentally responsible production.

5. Concord Group

A pioneer in urban construction and real estate, Concord Ready Mix provides reliable concrete products for both internal and external clients.

Key Features:

- Modern concrete mixing plants with automated systems.

- Supplies premium ready-mix concrete for high-rise buildings and infrastructure.

- Emphasis on quality, safety, and timely delivery.

6. Akij Ready Mix Concrete

Akij Group operates one of the fastest-growing ready-mix concrete divisions in Bangladesh.

Known for service reliability and modern production systems, Akij Ready Mix Concrete caters to developers and industrial clients.

Highlights:

- Large fleet of mixer trucks and transit mixers.

- Delivers high-quality concrete with strict quality control.

- Offers specialized and high-performance concrete for demanding projects.

7. LafargeHolcim Bangladesh PLC

A global leader in construction materials, LafargeHolcim Bangladesh offers ready-mix concrete solutions that combine innovation and sustainability.

The company’s eco-friendly materials and modern batching plants make it a preferred choice for sustainable construction.

Highlights:

- Offers premium ready-mix concrete with international standards.

- Focus on reducing human error through automated batching.

- Promotes environmentally responsible practices and green construction.

8. Shah Cement RMC (Abul Khair Group)

Shah Cement Industries Ltd. runs Shah Cement RMC, delivering high-quality ready-mix concrete across major cities.

Its strong mixing plants and transit delivery system support large-scale infrastructure and commercial projects.

Highlights:

- Uses leading cement brand for maximum consistency.

- Provides on-site mixing support for complex projects.

- Focus on construction excellence and reliable delivery.

9. Confidence Ready Mix

Confidence Group’s ready-mix concrete division is known for its dependability, durability, and modern construction practices.

The company supports large infrastructure and industrial projects with high-strength concrete.

Highlights:

- State-of-the-art ready-mix concrete plants.

- Fleet of transit mixers ensuring prompt delivery.

- Commitment to sustainability and continuous improvement.

10. ABC Building Products Ltd.

Part of ABC Group, this company has been a trusted concrete supplier since 2005.

It provides high-quality concrete using controlled mixing plants and ensures safe, efficient delivery to all project types.

Highlights:

- Specializes in pre-stressed and composite concrete.

- Focus on sustainable construction and client satisfaction.

- Offers custom mix designs for diverse construction needs.

What Is Ready-Mix Concrete?

Ready-mix concrete (RMC) is a precisely batched mixture of cement, sand, aggregates, and water, prepared at a ready-mix concrete plant and transported to the construction site in mixer trucks.

Advantages of Ready-Mix Concrete

- Consistent mix design and quality concrete.

- Saves time and reduces human error compared to on-site mixing.

- Ensures high-strength concrete suitable for residential, commercial, and infrastructure projects.

- Promotes sustainable construction practices and less material waste.

Ready-Mix Concrete vs On-Site Mixing

| Feature | Ready-Mix Concrete | On-Site Mixing |

|---|---|---|

| Quality | Controlled in batching plants. | Depends on manual skill and timing. |

| Efficiency | Fast, reliable delivery via transit mixers. | Slower and labor-intensive. |

| Cost | Reduces wastage and rework. | Requires more manpower and space. |

| Sustainability | Uses eco-friendly materials and ensures consistent quality. | Higher environmental impact. |

Ready Mix Concrete Companies Price in Bangladesh

The price of ready-mix concrete in Bangladesh depends on:

- Concrete grade (M20, M25, M30)

- Distance from the mixing plant to the site

- Type of project (residential, commercial, or infrastructure)

Bashundhara ReadyMix offers a competitive and transparent pricing structure, ensuring premium concrete quality with on-time delivery. Builders and contractors now rely on Ready Mix Concrete Companies for consistent strength, precision mix design, and eco-friendly materials. By using professional mixing plants and skilled technical teams, these suppliers ensure every batch meets construction standards.

Use a Ready Mix Concrete Calculator

A ready-mix concrete calculator helps estimate your project requirements accurately. Ready Mix Concrete Companies play a vital role in today’s fast-growing construction industry. These companies provide high-quality, durable, and sustainable concrete solutions that help builders save time and reduce waste. In Bangladesh, Ready Mix Concrete Companies are leading the way in modern infrastructure development with advanced batching plants, reliable delivery, and strict quality control.

Benefits:

- Prevents over-ordering or waste.

- Saves cost and planning time.

- Suitable for slabs, columns, driveways, and roads.

- Ensures better project management and sustainability.

Conclusion: Ready Mix Concrete Companies

The ready mix concrete companies in Bangladesh are driving modern, sustainable construction with high-quality concrete solutions.

Among them, Bashundhara ReadyMix continues to lead through strict quality control, reliable delivery, and a commitment to innovation and sustainability.

If you’re seeking premium ready-mix concrete solutions for your next project — whether residential, commercial, or industrial — choose Bashundhara ReadyMix, BSTI-certified, your trusted concrete provider in Bangladesh. Whether for residential, commercial, or industrial projects, Ready Mix Concrete Companies guarantee strong foundations and long-lasting performance — making them an essential part of the nation’s sustainable construction growth.

Frequently Asked Questions (FAQs)

Ready-mix concrete is produced in a batching plant under controlled conditions (cement, aggregates, water, and admixtures are finely measured), then transported via concrete mixer trucks to the site, ready for placement. This contrasts with on-site mixing, where materials are mixed on location, which often leads to variability in quality, increased labour/time, and more waste.

(See similar explanation on other sites.

Choosing one of the leading companies gives you benefits such as: documented quality control labs, stronger logistics/delivery networks, established track record on major projects, better ability to supply high grades/specialty mixes, stronger brand/reputation (which may impact future resale or warranty). When major infrastructure and high-rise buildings are involved, these factors become critical.

Some of the key criteria include:

- Quality assurance systems (batching plant, in-house lab)

- Delivery reliability (fleet size, geographic coverage)

- Range of mix grades and technical capability (e.g., high strength, self-compacting, special performance)

- Sustainability and environmental credentials

- Customer service and project experience (especially large developments)

These align with what competitor articles list.

Leading RMC suppliers usually offer standard grades like M20, M25, M30 etc., and also offer specialty mixes: high-strength concrete, self-compacting concrete (SCC), lean-mix for filling, high performance or durability mixes for infrastructure or high-rise building use. (As seen on top companies’ product pages like Crown Cement PLC).

While exact price will vary by company, region and mix grade, factors that influence cost include: mix grade (higher strength = more cement/admixture = cost up), distance of haulage from plant to site (logistics/time), pump or placement complexity, project size (bulk vs small), availability/supply conditions, and any special mix requirements. Some external estimates list Bangladesh RMC cost in the range (for typical mixes) of about BDT 5,500-6,500 per cubic meter, though actual quotes should be checked.

When you hire an RMC supplier, consider:

- Confirming the correct mix grade/order, slump/workability, delivery time (to avoid setting before placement).

- Ensuring your site access is appropriate for the mixer trucks/pumps.

- Checking the transit time and whether the supplier offers pump trucks if needed for height/overhead placement.

- Verifying that the supplier provides batch test certificates or quality assurance documentation.

- Planning for curing, finishing, and coordination with other trades to ensure the RMC’s benefits are fully realised.

Some advantages are:

- Uniform quality batch-to-batch — vital when structural loads are high.

- Reduced labour and on-site mixing equipment — less site disruption, faster placement.

- Better logistics integration (truck fleet, pumps) can help work at heights or with large pours.

- Potential for better sustainability (less waste, optimized mix) and safety (less manual handling).

Look for things like: company having in-house test labs, batch control systems, third-party certification or oversight (e.g., compliance with national/international standards). Also check for environmental credentials: use of recycled aggregates, waste reduction, energy efficient plants. These reflect the company’s commitment to quality and sustainable construction.

Transport and pump distances will depend on supplier’s fleet, pump equipment, and mix design (workability/time). Some companies quote capabilities of pumping vertical to high-rise floors and horizontally long distances. It’s important to discuss your project’s site constraints (height, distance, traffic, access) with the supplier and confirm they have the right equipment and logistics.

Common pitfalls include:

- Ordering the wrong mix grade for the structural requirement (leading to under-performance).

- Not accommodating delivery delays or transit time (which can affect setting and workability).

- Failing to coordinate site access / pump logistics, causing delays or increased cost.

- Choosing cheapest supplier without verifying quality control and past performance.

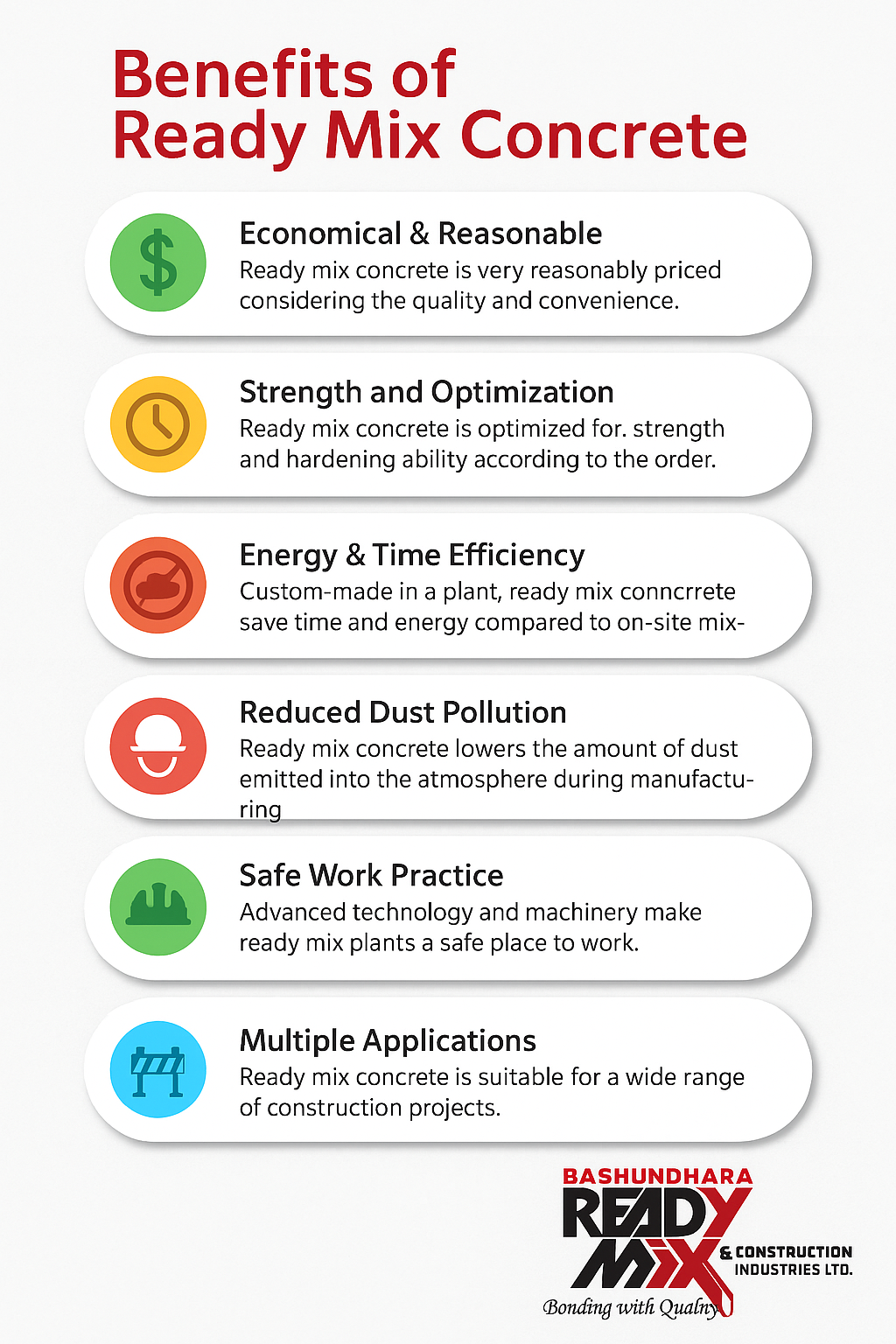

Benefits of Ready Mix concrete

Benefits of Ready Mix Concrete

Concrete is the backbone of modern infrastructure. From residential homes and commercial buildings to bridges, roads, and mega infrastructure projects, every construction depends on the strength, consistency, and durability of the concrete used. Traditionally, builders relied on site-mixed concrete, which was often labor-intensive, time-consuming, and prone to errors.

The introduction of ready mix concrete (RMC) has revolutionized the construction industry in Bangladesh and worldwide. Produced in advanced batching plants, RMC ensures precise mixing ratios, consistent quality, and timely delivery. At Bashundhara Ready Mix & Construction Industries Ltd. (BRMCIL), every batch is manufactured under strict supervision, tested in advanced labs, and certified by BUET to guarantee strength and reliability.

This article explores the key benefits of ready mix concrete, its advantages over traditional methods, and why it has become the preferred choice of contractors, developers, and engineers in Bangladesh. Now we know about benefits of ready mix concrete.

1. Economical & Cost-Effective

One of the biggest advantages of ready mix concrete is its cost efficiency. With site-mixed concrete, contractors face additional expenses due to:

Hiring more labor.

On-site equipment maintenance.

Higher material wastage.

Time delays that increase project budgets.

In contrast, ready mix concrete is reasonably priced, delivering high quality at competitive rates. The cost of ready mix concrete in Bangladesh becomes even more attractive when you factor in the savings on manpower, reduced construction time, and minimized wastage.

2. Superior Strength and Consistency

RMC is produced using automated batching plants that maintain uniform mix proportions. At BRMCIL, a 4D mixer system ensures that cement, sand, aggregates, and water are combined with precision.

Concrete grades are available from C15 (1,450 PSI) to C45 (6,525 PSI).

Each batch is designed according to project specifications.

Consistency is guaranteed across large volumes, reducing the risk of weak spots in structures.

This makes ready mix concrete a durable concrete solution for both small residential works and mega construction projects.

3. Time and Energy Efficiency

Manual mixing requires setting up equipment, measuring materials, and continuous supervision. This slows down progress and consumes significant energy.

Ready mix concrete suppliers in Bangladesh, like BRMCIL, address this by delivering concrete directly to the site:

Concrete arrives ready-to-use, cutting down preparation time.

Projects are completed faster, reducing overhead costs.

Labor requirements are minimized, improving construction efficiency.

For fast-track projects where deadlines are critical, RMC is the ideal solution.

4. Reduced Dust and Air Pollution

The best benefits of ready mix concrete are reduced air pollution. Site-mixed concrete creates large dust clouds, releasing fine cement particles into the air. This:

Reduces air quality at construction sites.

Causes health risks like respiratory problems.

Harms the surrounding environment.

By contrast, ready mix concrete production is centralized in batching plants, where dust is controlled and emissions minimized. This supports eco-friendly construction practices and ensures safer conditions for workers and nearby communities.

5. Safer Work Practices

Construction sites can be hazardous, especially when raw materials are handled manually. With ready mix concrete:

Automated plants reduce human handling.

Transit mixers deliver fresh concrete, minimizing on-site risks.

Workers operate in safer, more organized conditions.

At BRMCIL, strict health and safety policies are followed, ensuring safe working environments for employees, partners, and clients.

6. Reduction in Material Wastage

Traditional concrete mixing often results in leftover cement, aggregates, or sand. Managing and disposing of this waste increases costs and harms the environment. Another benefits of ready mix concrete is a reduction in material wastage.

Ready mix concrete reduces wastage by:

Producing only the required quantity for each project.

Using raw materials efficiently through computerized batching.

Allowing leftover concrete to be recycled into aggregates.

This makes RMC both an economical and sustainable construction material.

7. Wide Range of Applications

The benefits of ready mix concrete extend across diverse sectors. It can be tailored for use in:

Residential projects: Foundations, walls, floors, driveways, and footpaths.

Commercial developments: Office complexes, malls, and hotels.

Industrial structures: Warehouses, factories, and production units.

Civil engineering projects: Bridges, highways, tunnels, ports, and dams.

Urban infrastructure: Metro rails, flyovers, and airports.

This versatility makes RMC the go-to choice for engineers and contractors in Bangladesh.

8. Quality Assurance and BUET Certification

One of the most critical factors in construction is quality control. With manual mixing, achieving uniform quality is challenging. Benefits of ready mix concrete are quality assurance.

BRMCIL ensures reliability by:

Using computerized batching plants.

Testing samples in its quality control laboratory.

Maintaining certification from BUET for strength and durability.

This process guarantees that the concrete delivered to your site is consistent, reliable, and compliant with industry standards.

9. Eco-Friendly and Sustainable Construction

Sustainability is at the heart of modern construction. The ready mix concrete industry in Bangladesh contributes to this goal by:

Reducing dust and air pollution.

Conserving natural resources through optimized material usage.

Recycling leftover concrete into smaller aggregates.

Supporting green building initiatives for long-term environmental health.

Builders aiming for eco-friendly construction in Bangladesh can rely on ready mix concrete as a sustainable choice. Eco-friendly construction is benefits of ready mix concrete.

10. Long-Term Durability and Reliability

Most benefits of ready mix concrete are long-term durability. Ultimately, every builder wants a structure that lasts. Ready mix concrete provides:

High compressive strength, ensuring structural safety.

Greater resistance to weather, water seepage, and heavy loads.

Lower long-term maintenance costs.

This makes it a future-proof investment for developers, contractors, and homeowners alike.

Comparison: Ready Mix Concrete vs Site-Mixed Concrete

| Aspect | Ready Mix Concrete (RMC) | Site-Mixed Concrete |

|---|---|---|

| Quality | Consistent, BUET-certified | Varies by labor & conditions |

| Cost | Economical in bulk projects | Higher due to waste & labor |

| Time | Delivered ready-to-use | Time-consuming setup & mixing |

| Safety | Automated, safer processes | Manual, risk of accidents |

| Environment | Low dust & waste | High dust, more pollution |

This comparison clearly shows why ready mix concrete suppliers in Bangladesh like BRMCIL are rapidly replacing traditional mixing methods.

Bashundhara Ready Mix: benefits of ready mix concrete

The benefits of ready mix concrete are extensive — from cost-effectiveness, superior strength, and faster project completion to eco-friendliness, safety, and multiple applications. For Bangladesh’s growing construction industry, RMC is more than just a modern alternative — it is a necessity for building durable, sustainable, and reliable structures.

At Bashundhara Ready Mix & Construction Industries Ltd. (BRMCIL), every batch of RMC is manufactured with precision, tested for quality, and delivered with efficiency. Whether for residential housing, commercial complexes, or mega infrastructure projects, BRMCIL continues to be a trusted leader among ready mix concrete suppliers in Bangladesh.

For more about our specialized products, explore Green & Durable Concrete and Fast Track Concrete.

Ready Mix Concrete Outplays Traditional Concrete in Every Aspect

Ready Mix Concrete Outplays Traditional Concrete in Every Aspect

The quality of concrete determines the strength, durability, and safety of every construction project. Whether it’s roads, bridges, tunnels, homes, or high-rise buildings, concrete is the most critical building material. Over time, engineers have realized that ready mix concrete outplays traditional concrete by offering higher quality, faster delivery, and greater efficiency.

Unlike on-site manual mixing, which is prone to errors, ready mix concrete is produced in modern batching plants under strict quality control. With precision mixing, premium raw materials, and expert monitoring, ready mix concrete outplays traditional concrete in every category — from cost-effectiveness to sustainability.

Quality Makes the Difference

When comparing both methods, the superior quality of ready mix concrete outplays traditional concrete every time.

RMC: Uses top-grade cement, Sylhet sand, crushed aggregates, and admixtures from global leaders like Sika AG. Each batch is BUET-certified and tested in advanced labs.

Traditional Concrete: Mixed manually, often with poor ratios and contaminated raw materials stored at sites.

The result is clear: ready mix concrete outplays traditional concrete in ensuring consistent strength and durability.

Accurate Mixing Ratio

Concrete strength depends on accurate proportions of cement, sand, water, and aggregates.

RMC Advantage: Automated batching plants maintain exact ratios, producing concrete with PSI strength from C15 (1,450 PSI) to C45 (6,525 PSI).

Traditional Mixing: Inconsistent ratios due to manual measurement often compromise quality.

This is another area where ready mix concrete outplays traditional concrete with precision.

Speed and Efficiency

In construction, time equals money. Ready mix concrete outplays traditional concrete by reducing project delays and increasing efficiency.

RMC: Delivered ready-to-use in transit mixers. Saves labor, storage space, and preparation time.

Traditional Mixing: Requires more labor, site storage, and longer preparation.

For urgent projects, solutions like Fast Track Concrete ensure timely results.

Workforce and Safety

Safety is a vital factor in modern construction.

RMC: Fewer workers are needed since mixing is handled at the plant. Automated systems make operations safer.

Traditional Concrete: Requires heavy manual labor, increasing the risk of accidents.

Again, ready mix concrete outplays traditional concrete by promoting safer work practices.

Storage and Site Management

Urban construction sites have limited space. Ready mix concrete outplays traditional concrete here too.

RMC: No need for raw material stockpiles. Concrete is delivered fresh.

Traditional Mixing: Needs large storage areas for sand, stone, and cement, which are prone to contamination.

Environmental Sustainability

Sustainable construction is now essential.

RMC: Reduces dust, minimizes waste, and supports recycling of leftover concrete.

Traditional Concrete: Produces dust pollution, wastes raw materials, and harms the environment.

For eco-friendly building, ready mix concrete outplays traditional concrete every step of the way. Learn more in our guide on the Benefits of Ready Mix Concrete.

Consistency in Quality Control

Consistency is what makes structures durable. Ready mix concrete outplays traditional concrete with rigorous quality checks.

RMC: Monitored by skilled engineers and tested for workability, compressive strength, and durability with validation from BUET.

Traditional Mixing: Dependent on labor skills, resulting in unreliable output.

Cost Efficiency

Some assume RMC is costlier, but in reality ready mix concrete outplays traditional concrete in saving costs long-term.

Reduces labor expenses.

Cuts wastage of raw materials.

Speeds up completion, lowering project overheads.

Ensures durability, reducing maintenance costs.

Wide Range of Applications

The versatility of RMC means ready mix concrete outplays traditional concrete in different applications:

Residential projects: floors, driveways, homes.

Commercial buildings: malls, hotels, offices.

Infrastructure: highways, bridges, metro rail.

Industrial works: factories, warehouses.

For specialized needs, BRMCIL offers Special Performance Concrete tailored to challenging conditions.

Conclusion

The comparison is undeniable — ready mix concrete outplays traditional concrete in every aspect. It ensures higher quality, greater consistency, faster delivery, better safety, and eco-friendly practices.

At Bashundhara ReadyMix & Construction Industries Ltd. (BRMCIL), concrete is produced with advanced technology, BUET certification, and strict quality control, making it the top choice for Bangladesh’s construction sector.

When it comes to building the future, ready mix concrete outplays traditional concrete without question.

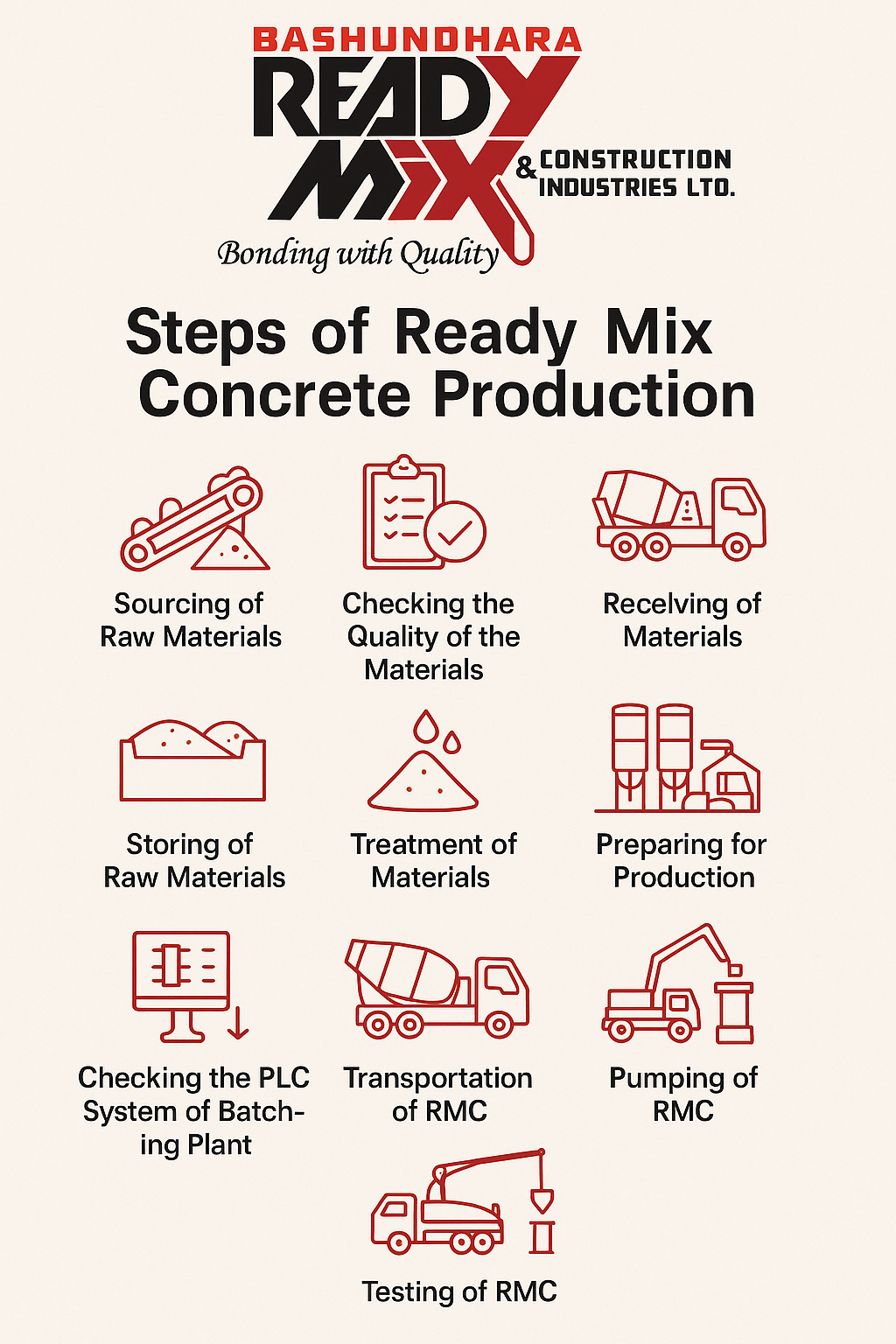

Manufacturing Process of Ready Mix Concrete

Manufacturing Process of Ready Mix Concrete

Concrete is the backbone of modern infrastructure. From residential buildings and commercial complexes to mega projects like bridges, highways, and airports, every structure depends on the strength, durability, and consistency of the concrete used. Over the past decade, ready mix concrete in Bangladesh has become increasingly popular due to its precision, cost-effectiveness, and time-saving benefits.

Unlike traditional on-site mixing, which often results in inconsistencies and delays, ready mix concrete (RMC) is produced in a controlled environment within a batching plant. Here, raw materials such as cement, aggregates, sand, and water are measured precisely, combined in specific proportions, and delivered to construction sites in transit mixers.

Manufacturing Process of Ready Mix Concrete at BRMCIL

At Bashundhara ReadyMix & Construction Industries Ltd. (BRMCIL), the manufacturing process of ready mix concrete follows a strict sequence of steps to guarantee BUET-certified quality, strength, and sustainability. This article explains the step-by-step production process and highlights why BRMCIL is one of the most trusted providers of ready mix concrete in Bangladesh.

Step 1: Sourcing of Raw Materials

Manufacturing Process of Ready Mix Concrete The process begins with the careful selection and sourcing of raw materials, which form the foundation of high-quality concrete. BRMCIL sources:

-

Bashundhara Cement (OPC/PCC): One of the strongest cement brands in Bangladesh, ensuring compressive strength and durability.

-

Sylhet Sand: Known for its purity and consistency.

-

Crushed Stone Chips: Sized and graded for stability and structural integrity.

-

Additives and Admixtures: Premium brands like Sika AG are used to enhance workability, water resistance, and long-term durability.

By sourcing only the best materials, BRMCIL ensures that every batch of concrete begins with a solid foundation of quality.

Step 2: Quality Inspection of Materials

Once raw materials arrive at the batching plant, they undergo stringent quality checks. Engineers test for:

-

Grain size distribution of aggregates

-

Moisture content of sand

-

Cement fineness and consistency

-

Chemical composition of admixtures

This ensures that only approved materials are used in the production of ready mix concrete.

Step 3: Receiving and Storage

Step three in the Manufacturing Process of Ready Mix Concrete. After inspection, materials are carefully stored to prevent contamination:

-

Cement is kept in silos to protect it from moisture.

-

Sand and aggregates are stored separately in designated stockpiles.

-

Admixtures are stored in sealed containers to preserve their chemical integrity.

Proper storage safeguards material quality before production begins.

Step 4: Treatment of Materials

Step Four in the Manufacturing Process of Ready Mix Concrete. Raw materials like sand and aggregates are treated through washing and watering to remove dust, impurities, or unwanted particles. This step ensures that the mix remains clean and consistent, which is critical for achieving the desired PSI strength.

Step 5: Preparing for Production

Before concrete mixing starts, technicians conduct pre-production checks:

-

Verifying the Programmable Logic Controller (PLC) system in the batching plant.

-

Checking the calibration of scales and measuring equipment.

-

Inspecting pumps, conveyors, and silos to ensure proper functioning.

This preparation ensures that the production environment is fully optimized.

Step 6: Automated Mixing in the Batching Plant

The heart of the manufacturing process of ready mix concrete is automated batching. Using advanced systems, precise proportions of cement, sand, water, and aggregates are measured and fed into the mixer.

The mixing process involves:

-

Dry Mixing: Initial blending of cement, sand, and aggregates.

-

Wet Mixing: Addition of water and admixtures for consistency.

This ensures a uniform, high-quality concrete mix tailored to customer specifications.

Step 7: Loading into Transit Mixer

Manufacturing Process of Ready Mix Concrete. Once mixed, the fresh concrete is transferred into a ready mix truck (transit mixer). The drum keeps rotating continuously to prevent the concrete from hardening during transport. This guarantees that the RMC remains workable upon arrival at the construction site.

Step 8: Transportation of Ready Mix Concrete

Manufacturing Process of Ready Mix Concrete BRMCIL operates a dedicated fleet of transit mixers, concrete pumps, and boom pumps to deliver concrete across project sites in Dhaka and other regions. Transportation is planned to minimize delays, ensuring concrete reaches sites in its fresh, mixed state.

For example, BRMCIL’s plants at Kanchan and Baridhara allow for efficient supply to Bashundhara Residential Area, Purbachal, Gulshan, Uttara, Tongi, and Mirpur.

Step 9: Pumping of Ready Mix Concrete

At the project site, concrete is pumped directly to the required location using concrete pumps or boom pumps. This technology ensures that concrete can be placed quickly, even at elevated heights in high-rise towers or across large-scale industrial foundations.

Step 10: Sampling and Testing

Step ten in the manufacturing Process of Ready Mix Concrete. To maintain transparency and compliance, BRMCIL conducts real-time testing of every batch of RMC. Tests include:

-

Slump Test: To measure workability.

-

Cylinder or Cube Tests: To verify compressive strength.

-

Moisture and Temperature Checks: To ensure consistency.

These samples are tested in BRMCIL’s quality control laboratory, and results are verified by independent certification from BUET.

Step 11: Curing and Strength Development Monitoring

An often-overlooked part of the ready mix concrete manufacturing process is monitoring how the concrete develops strength after placement. While BRMCIL delivers RMC in fresh condition, its team also provides guidance on curing practices to ensure long-term performance.

-

Curing Methods: Water curing, membrane curing, or chemical curing are recommended based on project requirements.

-

Strength Development: Continuous testing ensures concrete achieves its designed compressive strength (e.g., 28-day PSI values).

-

Durability Monitoring: Ensuring reduced cracks, shrinkage, and enhanced lifespan for critical infrastructure projects.

This added focus on post-production performance makes BRMCIL’s ready mix concrete reliable for mega projects as well as residential applications.

Why BRMCIL’s Manufacturing Process Stands Out

Manufacturing Process of Ready Mix Concrete at BRMCIL:

-

Precision Technology – Automated batching plants ensure exact mix proportions.

-

BUET Certification – Concrete is independently tested for compliance and strength.

-

End-to-End Control – From raw material sourcing to delivery, all processes are managed in-house.

-

Wide Strength Range – Customized grades from C15 (1,450 PSI) to C45 (6,525 PSI).

-

Eco-Friendly Practices – Optimized water usage, reduced wastage, and sustainable sourcing.

-

Curing Support – BRMCIL goes beyond production to ensure long-term concrete durability.

Applications of BRMCIL Ready Mix Concrete

BRMCIL’s ready mix concrete is used across multiple sectors:

-

Residential Construction: Homes, apartments, and housing complexes.

-

Commercial Projects: Shopping malls, offices, and hotels.

-

Industrial Facilities: Warehouses, factories, and power plants.

-

Infrastructure Projects: Roads, bridges, ports, and metro rail projects.

Each application benefits from high strength, consistency, and timely delivery.

Conclusion

The manufacturing process of ready mix concrete at BRMCIL is built on technology, quality, and sustainability. By carefully sourcing raw materials, using advanced batching plants, ensuring precise mixing, conducting BUET-certified testing, and guiding clients on proper curing, BRMCIL guarantees reliable concrete solutions.

With strategically located plants in Hasnabad, Kanchan, and Baridhara, BRMCIL continues to lead the ready mix concrete industry in Bangladesh, supporting the nation’s growth with durable, eco-friendly, and high-performance concrete.

For more about our specialized products, explore Green & Durable Concrete and Special Performance Concrete.