Manufacturing Process of Ready Mix Concrete

Concrete is the backbone of modern infrastructure. From residential buildings and commercial complexes to mega projects like bridges, highways, and airports, every structure depends on the strength, durability, and consistency of the concrete used. Over the past decade, ready mix concrete in Bangladesh has become increasingly popular due to its precision, cost-effectiveness, and time-saving benefits.

Unlike traditional on-site mixing, which often results in inconsistencies and delays, ready mix concrete (RMC) is produced in a controlled environment within a batching plant. Here, raw materials such as cement, aggregates, sand, and water are measured precisely, combined in specific proportions, and delivered to construction sites in transit mixers.

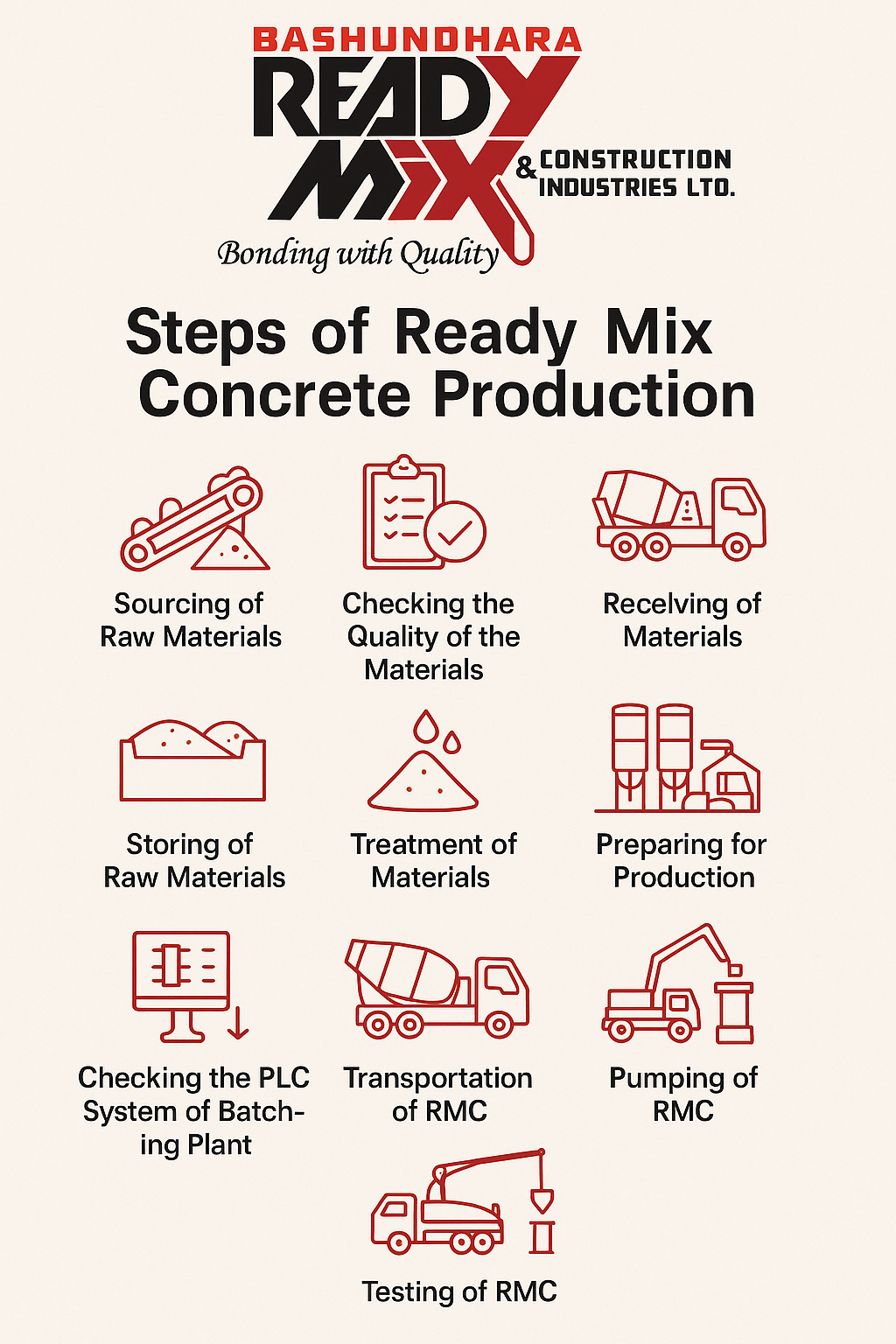

Manufacturing Process of Ready Mix Concrete at BRMCIL

At Bashundhara ReadyMix & Construction Industries Ltd. (BRMCIL), the manufacturing process of ready mix concrete follows a strict sequence of steps to guarantee BUET-certified quality, strength, and sustainability. This article explains the step-by-step production process and highlights why BRMCIL is one of the most trusted providers of ready mix concrete in Bangladesh.

Step 1: Sourcing of Raw Materials

Manufacturing Process of Ready Mix Concrete The process begins with the careful selection and sourcing of raw materials, which form the foundation of high-quality concrete. BRMCIL sources:

-

Bashundhara Cement (OPC/PCC): One of the strongest cement brands in Bangladesh, ensuring compressive strength and durability.

-

Sylhet Sand: Known for its purity and consistency.

-

Crushed Stone Chips: Sized and graded for stability and structural integrity.

-

Additives and Admixtures: Premium brands like Sika AG are used to enhance workability, water resistance, and long-term durability.

By sourcing only the best materials, BRMCIL ensures that every batch of concrete begins with a solid foundation of quality.

Step 2: Quality Inspection of Materials

Once raw materials arrive at the batching plant, they undergo stringent quality checks. Engineers test for:

-

Grain size distribution of aggregates

-

Moisture content of sand

-

Cement fineness and consistency

-

Chemical composition of admixtures

This ensures that only approved materials are used in the production of ready mix concrete.

Step 3: Receiving and Storage

Step three in the Manufacturing Process of Ready Mix Concrete. After inspection, materials are carefully stored to prevent contamination:

-

Cement is kept in silos to protect it from moisture.

-

Sand and aggregates are stored separately in designated stockpiles.

-

Admixtures are stored in sealed containers to preserve their chemical integrity.

Proper storage safeguards material quality before production begins.

Step 4: Treatment of Materials

Step Four in the Manufacturing Process of Ready Mix Concrete. Raw materials like sand and aggregates are treated through washing and watering to remove dust, impurities, or unwanted particles. This step ensures that the mix remains clean and consistent, which is critical for achieving the desired PSI strength.

Step 5: Preparing for Production

Before concrete mixing starts, technicians conduct pre-production checks:

-

Verifying the Programmable Logic Controller (PLC) system in the batching plant.

-

Checking the calibration of scales and measuring equipment.

-

Inspecting pumps, conveyors, and silos to ensure proper functioning.

This preparation ensures that the production environment is fully optimized.

Step 6: Automated Mixing in the Batching Plant

The heart of the manufacturing process of ready mix concrete is automated batching. Using advanced systems, precise proportions of cement, sand, water, and aggregates are measured and fed into the mixer.

The mixing process involves:

-

Dry Mixing: Initial blending of cement, sand, and aggregates.

-

Wet Mixing: Addition of water and admixtures for consistency.

This ensures a uniform, high-quality concrete mix tailored to customer specifications.

Step 7: Loading into Transit Mixer

Manufacturing Process of Ready Mix Concrete. Once mixed, the fresh concrete is transferred into a ready mix truck (transit mixer). The drum keeps rotating continuously to prevent the concrete from hardening during transport. This guarantees that the RMC remains workable upon arrival at the construction site.

Step 8: Transportation of Ready Mix Concrete

Manufacturing Process of Ready Mix Concrete BRMCIL operates a dedicated fleet of transit mixers, concrete pumps, and boom pumps to deliver concrete across project sites in Dhaka and other regions. Transportation is planned to minimize delays, ensuring concrete reaches sites in its fresh, mixed state.

For example, BRMCIL’s plants at Kanchan and Baridhara allow for efficient supply to Bashundhara Residential Area, Purbachal, Gulshan, Uttara, Tongi, and Mirpur.

Step 9: Pumping of Ready Mix Concrete

At the project site, concrete is pumped directly to the required location using concrete pumps or boom pumps. This technology ensures that concrete can be placed quickly, even at elevated heights in high-rise towers or across large-scale industrial foundations.

Step 10: Sampling and Testing

Step ten in the manufacturing Process of Ready Mix Concrete. To maintain transparency and compliance, BRMCIL conducts real-time testing of every batch of RMC. Tests include:

-

Slump Test: To measure workability.

-

Cylinder or Cube Tests: To verify compressive strength.

-

Moisture and Temperature Checks: To ensure consistency.

These samples are tested in BRMCIL’s quality control laboratory, and results are verified by independent certification from BUET.

Step 11: Curing and Strength Development Monitoring

An often-overlooked part of the ready mix concrete manufacturing process is monitoring how the concrete develops strength after placement. While BRMCIL delivers RMC in fresh condition, its team also provides guidance on curing practices to ensure long-term performance.

-

Curing Methods: Water curing, membrane curing, or chemical curing are recommended based on project requirements.

-

Strength Development: Continuous testing ensures concrete achieves its designed compressive strength (e.g., 28-day PSI values).

-

Durability Monitoring: Ensuring reduced cracks, shrinkage, and enhanced lifespan for critical infrastructure projects.

This added focus on post-production performance makes BRMCIL’s ready mix concrete reliable for mega projects as well as residential applications.

Why BRMCIL’s Manufacturing Process Stands Out

Manufacturing Process of Ready Mix Concrete at BRMCIL:

-

Precision Technology – Automated batching plants ensure exact mix proportions.

-

BUET Certification – Concrete is independently tested for compliance and strength.

-

End-to-End Control – From raw material sourcing to delivery, all processes are managed in-house.

-

Wide Strength Range – Customized grades from C15 (1,450 PSI) to C45 (6,525 PSI).

-

Eco-Friendly Practices – Optimized water usage, reduced wastage, and sustainable sourcing.

-

Curing Support – BRMCIL goes beyond production to ensure long-term concrete durability.

Applications of BRMCIL Ready Mix Concrete

BRMCIL’s ready mix concrete is used across multiple sectors:

-

Residential Construction: Homes, apartments, and housing complexes.

-

Commercial Projects: Shopping malls, offices, and hotels.

-

Industrial Facilities: Warehouses, factories, and power plants.

-

Infrastructure Projects: Roads, bridges, ports, and metro rail projects.

Each application benefits from high strength, consistency, and timely delivery.

Conclusion

The manufacturing process of ready mix concrete at BRMCIL is built on technology, quality, and sustainability. By carefully sourcing raw materials, using advanced batching plants, ensuring precise mixing, conducting BUET-certified testing, and guiding clients on proper curing, BRMCIL guarantees reliable concrete solutions.

With strategically located plants in Hasnabad, Kanchan, and Baridhara, BRMCIL continues to lead the ready mix concrete industry in Bangladesh, supporting the nation’s growth with durable, eco-friendly, and high-performance concrete.

For more about our specialized products, explore Green & Durable Concrete and Special Performance Concrete.